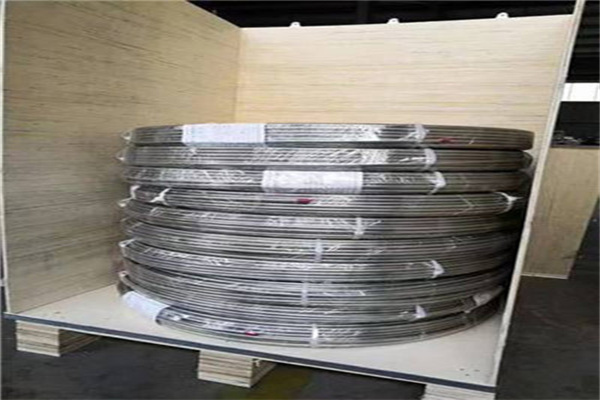

ASTM A213, A269 904L stainless hlau coiled tubing hauv Suav teb

Alloy 904L yog ib qho tsis ruaj khov, siab alloy austenitic stainless hlau nrog cov ntsiab lus qis.Nws yog dav siv nyob rau hauv daim ntawv thov qhov twg corrosion ntawm TP316 / L thiab TP317 / L tsis txaus.Lub alloy kuj muaj zoo heev formability, weldability, thiab toughness.Qhov sib ntxiv ntawm tooj liab muab alloy 904L corrosion resistant zog uas yog superior rau cov pa chrome nickel stainless hlau.Piv txwv muaj xws li tsis kam mus rau sulfuric, phosphoric, thiab acetic acids.

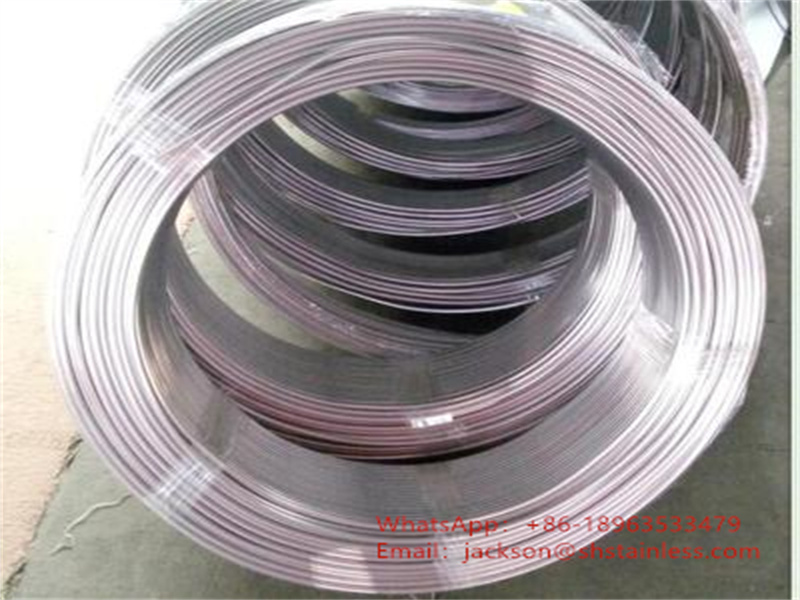

Qhov Loj

| Sab nraud Diameter (OD) | Phab ntsa Thickness |

| .250 "-1.000" | .035 "-.065" |

Cold tiav thiab ci annealed raj.

Kev xav tau tshuaj

Hlau alloy 904L (UNS N08904)

Cov ntsiab lus %

| C Cov pa roj carbon | Mn Manganese | P Phosphorus | S Sulfur | Si Silicon | Cr Chromium | Ni Nickel | Mo Molybdenum | N Nitrogen | Cu Tooj |

| 0.020 max | max 2.00 Nws | 0.040 max | 0.030 max | max 1.00 Nws | 19.0-23.0 Nws | 23.0-28.0 Nws | 4.0–5.0 | 0.10 max | 1.00–2.00 Nws |

Dimensional Tolerances

| OD | OD Tolerance | Phab ntsa Tolerance |

| ≤ .500 " | ± .005 " | ± 15% |

| 0.500-1.500 hli | ± .005 " | ± 10% |

Mechanical Properties

| Yield zog: | 31 kwm |

| Tensile zog: | 71 kwm |

| Elongation (min 2 "): | 35% |

| Hardness (Rockwell B Scale): | 90 HRB max |

Fabrication

Alloy 904L yog non-magnetic nyob rau hauv tag nrho cov mob thiab muaj zoo formability thiab weldability.Cov qauv austenitic kuj muab cov qib no zoo heev toughness, txawm mus rau cryogenic kub.

Kev lag luam kev siv

Cov txheej txheem tshuaj

Nws cov ntsiab lus siab chromium thiab npib tsib xee, nrog rau kev sib ntxiv ntawm molybdenum thiab tooj liab, pab alloy 904L sawv ntsug rau sulfuric, phosphoric thiab acetic acids.Qhov no yog tshwj xeeb tshaj yog pab tau nyob rau hauv zus tau tej cov acids thiab chiv.

Sau koj cov lus ntawm no thiab xa tuaj rau peb